NASA‘s Artemis program continues its forward march as technicians at the Michoud Assembly Facility in New Orleans meticulously move the core stage’s liquid hydrogen tank to a priming cell near the Vertical Assembly Building. This crucial step in the preparation for the Artemis III mission involves surface treatment by sanding down the tank before applying primer. The automated robotic tool precisely coats the barrel section, while manual application ensures thorough priming of the forward and aft domes. Post priming, the tank undergoes the application of a foam-based thermal protection system, safeguarding it from extreme temperatures during launch and flight. This tank, a pivotal component of the 212-foot-tall rocket stage, collaborates with the RS-25 engines to generate two million pounds of thrust, propelling NASA’s Orion spacecraft and astronauts towards the lunar surface for the Artemis mission.

Technicians at NASA‘s Michoud Assembly Facility engaged in a critical process for the upcoming Artemis IV lunar mission. The images captured reveal the meticulous removal of a weld-confidence article from a robotic welding tool. This article, comprising sections of a liquid hydrogen tank dome, serves as a vital test to ensure the precise welding required for the flight-ready dome. The dome is destined to be a crucial component of the exploration upper stage (EUS), a four-engine powerhouse for NASA’s Space Launch System (SLS) rocket. Set to replace the interim cryogenic propulsion stage (ICPS), the EUS is tailored for Artemis IV, employing a blend of liquid oxygen and liquid hydrogen to propel NASA’s Orion spacecraft, carrying cargo and crew to the Moon. While the featured weld-confidence article won’t journey to space, its role in certifying manufacturing procedures demonstrates the dedication to precision in advancing space exploration.

“These images show technicians at NASA’s Michoud Assembly Facility in New Orleans removing a weld-confidence article from a robotic welding tool in December 2023. This article features pieces of a liquid hydrogen tank dome that were welded as a test to make sure the dome used for flight will be welded correctly.

The dome will be part of the new, four-engine EUS (exploration upper stage) for NASA’s SLS (Space Launch System) rocket. EUS will be used for the Artemis IV lunar mission, replacing the single-engine interim cryogenic propulsion stage (ICPS) used for the first three Artemis missions. The evolved in-space stage will use a combination of liquid oxygen and liquid hydrogen propellants to help power the engines to send large cargo and crew inside NASA’s Orion spacecraft to the Moon. The weld-confidence article pictured here will not be used for flight but is instead helping teams prepare and certify the procedures needed to manufacture flight hardware.” – via NASA Image and Video Library

Offloading EUS Test Article Photos from NASA’s Michoud Assembly Facility

- Image credit: NASA / Eric Bordelon

- Image credit: NASA / Eric Bordelon

Futuramic’s Pioneering Role in Powering Deep Space Exploration

At the forefront of innovation and excellence, Futuramic takes center stage in shaping the future of deep space exploration. With a dynamic team exceeding 200 dedicated associates, Futuramic stands as a key player in the design, build, and maintenance of essential tooling, integral to assembling the core stage of the world’s most potent deep space exploration rocket. Fueled by liquid hydrogen and liquid oxygen, this core stage serves a critical role in propelling both the crew capsule and service module from Earth’s surface to a high Earth orbit.

Venturing beyond the core stage, Futuramic’s influence extends to the production of large-scale structural flight hardware, notably contributing to Artemis II and upcoming missions. What distinguishes Futuramic is its proprietary, in-house developed manufacturing process, a testament to their innovative approach within the aerospace industry.

Futuramic’s unwavering commitment to quality and expertise positions them as an indispensable partner in advancing space exploration. Their significant contributions to the Artemis program underscore a dedication to pushing boundaries and realizing ambitious missions, expanding our comprehension of the Moon and beyond.

As we enter a new chapter in lunar exploration, Futuramic’s role becomes increasingly pivotal, setting the stage for future space missions. Their manufacturing prowess and consistent delivery of exceptional tooling and flight hardware affirm their unwavering commitment to excellence in the aerospace arena.

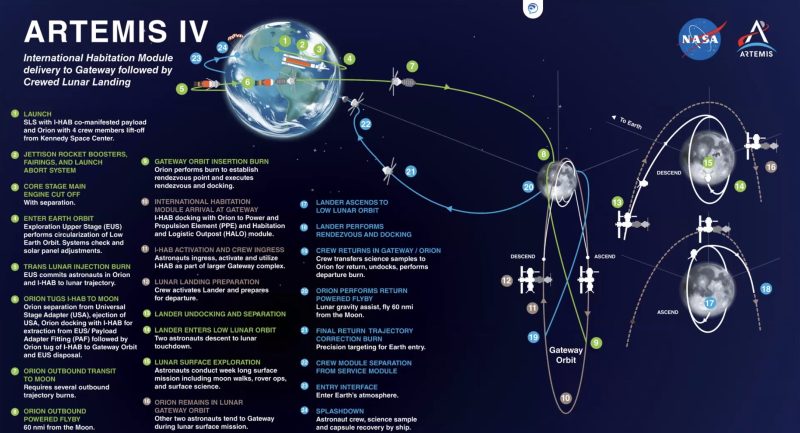

About Artemis IV

The Artemis IV mission is the fourth planned mission of the Artemis program and will see two astronauts land on the Moon as well as deliver the first ESA module for the Gateway: I-Hab. The launch will be on a Space Launch System rocket from the usual Launchpad 39B at NASA’s Kennedy Space Center in Florida, USA. The mega Moon rocket will propel four astronauts inside Orion to the Moon but Artemis IV will be the first mission to use a new second stage, replacing the interim cryogenic propulsion stage used on the first three Artemis missions. The advanced exploration upper stage booster increases the SLS’s rocket’s capability from 27 to 42 tonnes, allowing for more hardware to be sent to the Moon with the Orion spacecraft.