Equipment

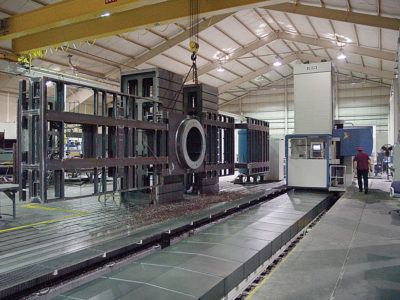

One of the largest Single Gantry CNC machines in the United States

Equipment

The right tools for the job

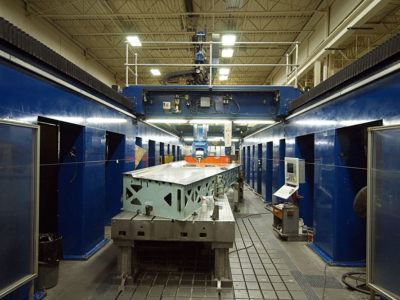

The largest 5-axis high speed gantry in North America, Ingersoll’s Cybermill®, is located right here at Futuramic. It’s only one of the many advanced tools we utilize to design, build, fabricate, and manufacture machined parts. With the Cybermill, we can handle the very big projects in the aerospace industry, but big isn’t all that we do. We have the advanced tools to handle a wide variety of projects, no matter the size. We utilize a full array of capital equipment, for all facets of fabrication and manufacturing. These are supported by Laser Tracker and large envelop CMM systems.

Select a category below to view our equipment.

Equipment » Manufacturing

Manufacturing that’s a step above the rest

Manufacturing Equipment

Quality from start to finish

Futuramic’s manufacturing capabilities utilizes the best tools for the job. Our state-of-the-art capital equipment includes 30 CNC machines and the largest 5-Axis gantry mill in North America. There is no job that we can’t handle from start to finish.

Automated Machinery

1 – Ingersoll 5-Axis High Speed Gantry

MODEL: Cybermill

X: 240' Y: 24' Z: 10'

A: 4th Axis Head C: 5th Axis Head

2 – 2 X Breton FLYMILL 5-Axis High Speed Machining Center

MODEL: 1000HD

X: 11.5' Y: 55' Z: 78.74'

A:4th Axis Head C: 5th Axis Head

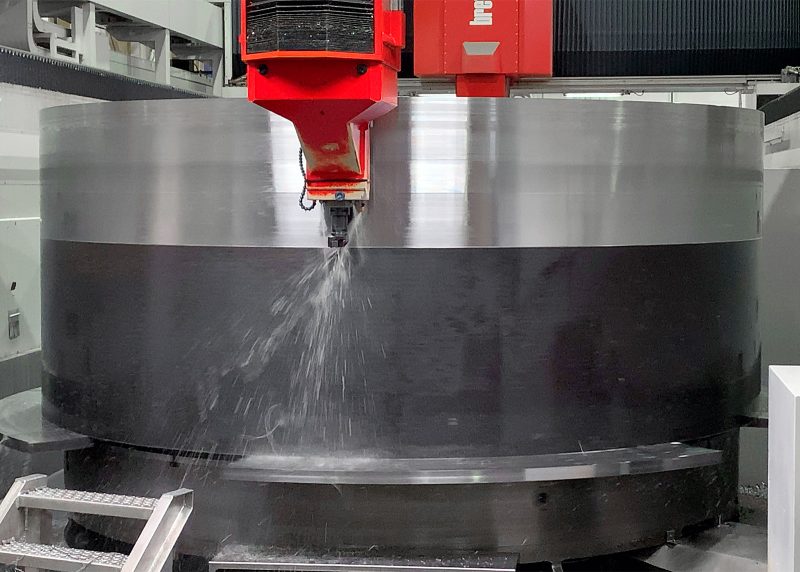

1 – Giddings & Lewis CNC Vertical Turning Center

MODEL: VTC 2500

X: 61.4” Z: 68.9”

Table Diameter: 98.43”

1 – Dayton 1200 High Speed Gantry Dual Head

MODEL: 1265

X: 816" Y: 182" Z: 60"

A: 4th Axis Head C: 5th Axis Head

1 – FPT Pragma High Speed Milling Machine

MODEL: K-408

X:236” Y:78” Z:47”

A:4th Axis Head C:5th Axis Head

1 – Breton Flymill High Speed Machining Center

MODEL: 1300

X: 138” Y: 312” Z: 78”

A: 4th Axis Head C: 5th Axis Head

1 – Breton Matrix High Speed Gantry

MODEL: 1300

X: 152” Y: 336” Z: 60”

A: 4th Axis Head C: 5th Axis Head

1 – Breton XCEEDER

MODEL: 1200 Heavy Duty

X: 47.2” Y: 39.4” Z: 27.6”

A: Axis Rotation: -30÷+120 C: Axis Rotation: continuous

1 – Machine Systems Horizontal Boring Mill

MODEL: DM30-09BO-728-CLD

X: 100” Y: 60” Z: 30”

B: 360 Degree N/C Rotary Table

Turntables

Heat Treat Oven

Tool Maker Equipment

1 – Okuma CNC Lathe

1 – Lathes 17” DIA

2 – Lathes 15” DIA

56 – Bridgeport Mills

2 – Cut Off Saws 36”

2 – OD Grinders

7 – Drill Presses 20”

3 – Welders

1 – Grisetti #800 Hydraulic ID Grinder 10”X6”

7 – Surface Grinders

7 – Metal Band Saws 20”

Equipment » Fabrication

We’re a cut above our competition

Fabrication Equipment

Shaped to your needs

Futuramic’s fabrication capabilities provide a complete solution from welding and cutting to metal forming. All our weld inspectors are AWS CWI Certified and our welders are qualified to AWS Standards. We have in-house training and qualification capability in all positions and in a wide range of materials.

Welding Equipment

Cutting Equipment

1 – Hypertherm Max200 Plasma Cutter

2” Plate Capacity

2 – Hypertherm Max100 Plasma Cutter

1” Plate Capacity

Metal Forming Equipment

2 – Piranha P3

50 Ton Ironworker

1 – Baileigh Roll Former

Material Size – 48” wide 3/8” height

1 – Lathe

1 – H-Frame Hydraulic Press

70 Ton

2 – Gantry Frame Hydraulic Press

75 Ton

1 – Blanchard Surface Grinding Machine

6 – Stationary Grinding & Sanding Machines

2 – Bridgeport Vertical Mill

1 – Radial Drill

3 – Drill Presses

Fabricator Equipment

1- 40” Sandblast Cabinet

3 – Air Compressors

10 - 25 Hp

Rotory Screw

1 – Air Compressors

10 Hp

12 – Fitting Tables

Up to 14 Ft. X 28 Ft. Planed Surface

Equipment » Inspection

Checked to meet the highest specification

Inspection Equipment

Laser accuracy

Futuramic employs a wide array of the latest laser trackers and large envelop coordinate measuring machines to check that a product conforms to a customer’s highest specification. These tools allow us to inspect and compare any part to the CAD data, identify any deviations, maximize efficiencies in the manufacturing process, and minimize rework costs.