Equipment

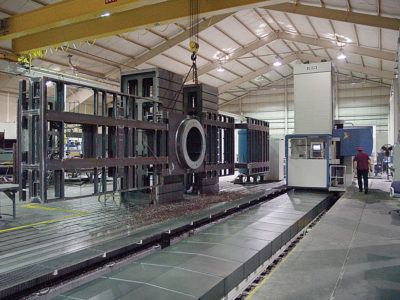

One of the largest Single Gantry CNC machines in the United States

Equipment

The right tools for the job

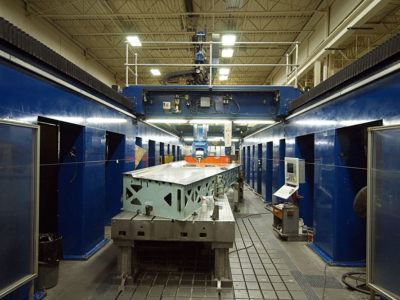

One of the largest 5-axis high-speed gantries in North America, Ingersoll’s Cybermill®, is located right here at Futuramic. It’s just one of the many advanced tools we use to design, build, fabricate, and machine precision parts. Our state-of-the-art equipment allows us to handle a wide variety of projects, regardless of size. We utilize a full array of capital equipment for all facets of fabrication and manufacturing, supported by laser trackers and large-envelope CMM systems.

Select a category below to view our equipment.

Equipment » Manufacturing

Manufacturing that’s a step above the rest

Manufacturing Equipment

Quality from start to finish

Futuramic’s manufacturing capabilities utilizes the best tools for the job. Our state-of-the-art capital equipment includes 30 CNC machines and the largest 5-Axis gantry mill in North America. There is no job that we can’t handle from start to finish.

Automated Machinery

1 – Ingersoll 5-Axis High Speed Gantry

MODEL: Cybermill

X: 240' Y: 24' Z: 10'

A: 4th Axis Head C: 5th Axis Head

2 – 2 X Breton FLYMILL 5-Axis High Speed Machining Center

MODEL: 1000HD

X: 11.5' Y: 55' Z: 78.74'

A:4th Axis Head C: 5th Axis Head

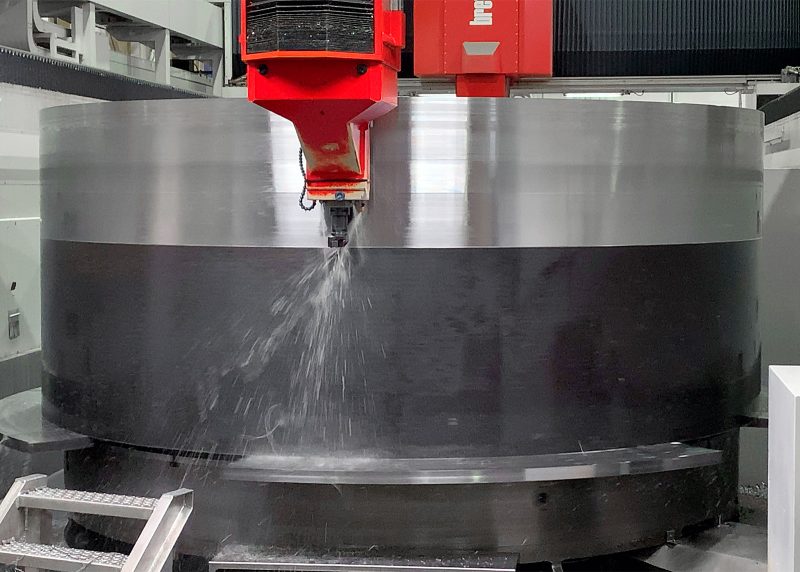

1 – Giddings & Lewis CNC Vertical Turning Center

MODEL: VTC 2500

X: 61.4” Z: 68.9”

Table Diameter: 98.43”

1 – Dayton 1200 High Speed Gantry Dual Head

MODEL: 1265

X: 816" Y: 182" Z: 60"

A: 4th Axis Head C: 5th Axis Head

1 – FPT Pragma High Speed Milling Machine

MODEL: K-408

X:236” Y:78” Z:47”

A:4th Axis Head C:5th Axis Head

1 – Breton Flymill High Speed Machining Center

MODEL: 1300

X: 138” Y: 312” Z: 78”

A: 4th Axis Head C: 5th Axis Head

1 – Breton Matrix High Speed Gantry

MODEL: 1300

X: 152” Y: 336” Z: 60”

A: 4th Axis Head C: 5th Axis Head

1 – Breton XCEEDER

MODEL: 1200 Heavy Duty

X: 47.2” Y: 39.4” Z: 27.6”

A: Axis Rotation: -30÷+120 C: Axis Rotation: continuous

1 – Machine Systems Horizontal Boring Mill

MODEL: DM30-09BO-728-CLD

X: 100” Y: 60” Z: 30”

B: 360 Degree N/C Rotary Table

Turntables

Heat Treat Oven

Tool Maker Equipment

1 – Okuma CNC Lathe

1 – Lathes 17” DIA

2 – Lathes 15” DIA

56 – Bridgeport Mills

2 – Cut Off Saws 36”

2 – OD Grinders

7 – Drill Presses 20”

3 – Welders

1 – Grisetti #800 Hydraulic ID Grinder 10”X6”

7 – Surface Grinders

7 – Metal Band Saws 20”

Equipment » Fabrication

We’re a cut above our competition

Fabrication Equipment

Shaped to your needs

Futuramic’s fabrication capabilities provide a complete solution from welding and cutting to metal forming. All our weld inspectors are AWS CWI Certified and our welders are qualified to AWS Standards. We have in-house training and qualification capability in all positions and in a wide range of materials.

Welding Equipment

Cutting Equipment

1 – Hypertherm Max200 Plasma Cutter

2” Plate Capacity

2 – Hypertherm Max100 Plasma Cutter

1” Plate Capacity

Metal Forming Equipment

2 – Piranha P3

50 Ton Ironworker

1 – Baileigh Roll Former

Material Size – 48” wide 3/8” height

1 – Lathe

1 – H-Frame Hydraulic Press

70 Ton

2 – Gantry Frame Hydraulic Press

75 Ton

1 – Blanchard Surface Grinding Machine

6 – Stationary Grinding & Sanding Machines

2 – Bridgeport Vertical Mill

1 – Radial Drill

3 – Drill Presses

Fabricator Equipment

1- 40” Sandblast Cabinet

3 – Air Compressors

10 - 25 Hp

Rotary Screw

1 – Air Compressors

10 Hp

12 – Fitting Tables

Up to 14 Ft. X 28 Ft. Planed Surface

Equipment » Inspection

Checked to meet the highest specification

Inspection Equipment

Laser accuracy

Futuramic employs a wide array of the latest laser trackers and large envelop coordinate measuring machines to check that a product conforms to a customer’s highest specification. These tools allow us to inspect and compare any part to the CAD data, identify any deviations, maximize efficiencies in the manufacturing process, and minimize rework costs.