Artemis III hardware is on the move!

Liquid Hydrogen Tank for Artemis III

NASA’s Space Launch System’s liquid hydrogen tank was recently moved into a new work area at NASA’s Michoud Assembly Facility to perform scans of the tank’s dimensions in preparation for multiple join activities that will happen throughout the manufacturing process.

“Technicians at NASA’s Michoud Assembly Facility in New Orleans move the liquid hydrogen tank of NASA’s Space Launch System (SLS) rocket to Cell A for white light scans of the tank’s dimensions in preparation of multiple join activities throughout the manufacturing process. The flight hardware will be used for Artemis III, one of the first crewed Artemis missions. The liquid hydrogen tank holds 537,000 gallons of liquid hydrogen cooled to minus 432 degrees Fahrenheit and is the largest of the five elements that make up the rocket’s 212-foot-tall core stage. The liquid hydrogen tank is situated between the core stage’s intertank and engine section. The liquid hydrogen hardware, along with the liquid oxygen tank, will provide propellant to the four RS-25 engines at the bottom of the core stage to produce more than two million pounds of thrust to launch NASA’s Artemis missions to the Moon. Together with its four RS-25 engines, the rocket’s massive 212-foot-tall core stage — the largest stage NASA has ever built — and its twin solid rocket boosters produce 8.8 million pounds of thrust to send NASA’s Orion spacecraft, astronauts and supplies beyond Earth’s orbit to the Moon and, ultimately, Mars. Offering more payload mass, volume capability and energy to speed missions through space, the SLS rocket, along with NASA’s Gateway in lunar orbit, the Human Landing System, and Orion spacecraft, is part of NASA’s backbone for deep space exploration and the Artemis lunar program. No other rocket is capable of carrying astronauts in Orion around the Moon in a single mission.” – via NASA Image and Video Library

- Image credit: NASA/Michael DeMocker

- Image credit: NASA/Michael DeMocker

- Image credit: NASA/Michael DeMocker

Futuramic’s Cell A Removable Assembly Platform and OHME at NASA’s Michoud Assembly Facility

Forward Skirt for Artemis III SLS Core Stage

The forward skirt of NASA’s Space Launch System (SLS) wa salso moved in preparation to apply the thermal protection system to the flight hardware, which will protect it from the extreme temperatures during launch and flight.

“Crews at NASA’s NASA’s Michoud Assembly Facility in New Orleans move the forward skirt of NASA’s Space Launch System (SLS) rocket to another part of the facility Dec. 15. Teams are preparing to apply the thermal protection system to the flight hardware, which will protect it from the extreme temperatures during launch and flight. The forward skirt is part of the core stage that will power the SLS rocket for the Artemis III mission. The forward skirt houses flight computers, cameras, and avionics. The SLS core stage is made up of five unique elements: the forward skirt, liquid oxygen tank, intertank, liquid hydrogen tank, and the engine section. When fully stacked, the forward skirt is located at the top of the core stage and connects the stage to the upper part of the rocket. Together with its four RS-25 engines, the rocket’s massive 212-foot-tall core stage — the largest stage NASA has ever built — and its twin solid rocket boosters produce 8.8 million pounds of thrust to send NASA’s Orion spacecraft, astronauts and supplies beyond Earth’s orbit to the Moon and, ultimately, Mars. Offering more payload mass, volume capability and energy to speed missions through space, the SLS rocket, along with NASA’s Gateway in lunar orbit, the Human Landing System, and Orion spacecraft, is part of NASA’s backbone for deep space exploration and the Artemis lunar program. No other rocket is capable of carrying astronauts in Orion around the Moon in a single mission.” – via NASA Image and Video Library

- Image credit: NASA/Jared Lyons

- Image credit: NASA/Jared Lyons

- Image credit: NASA/Jared Lyons

- Image credit: NASA/Jared Lyons

- Image credit: NASA/Jared Lyons

- Image credit: NASA/Jared Lyons

Aerospace Installation Support

Futuramic’s full working mobile machine shop. shown here at NASA’s Michoud Assembly Facility in Louisiana.

Futuramic has found this installation support so valuable for both us and our customers that we have added a second and third mobile machine shop. The machine trailers are fully self-sufficient with the option of two power sources: natural gas/flexible gas generator or plug-in electrical power.

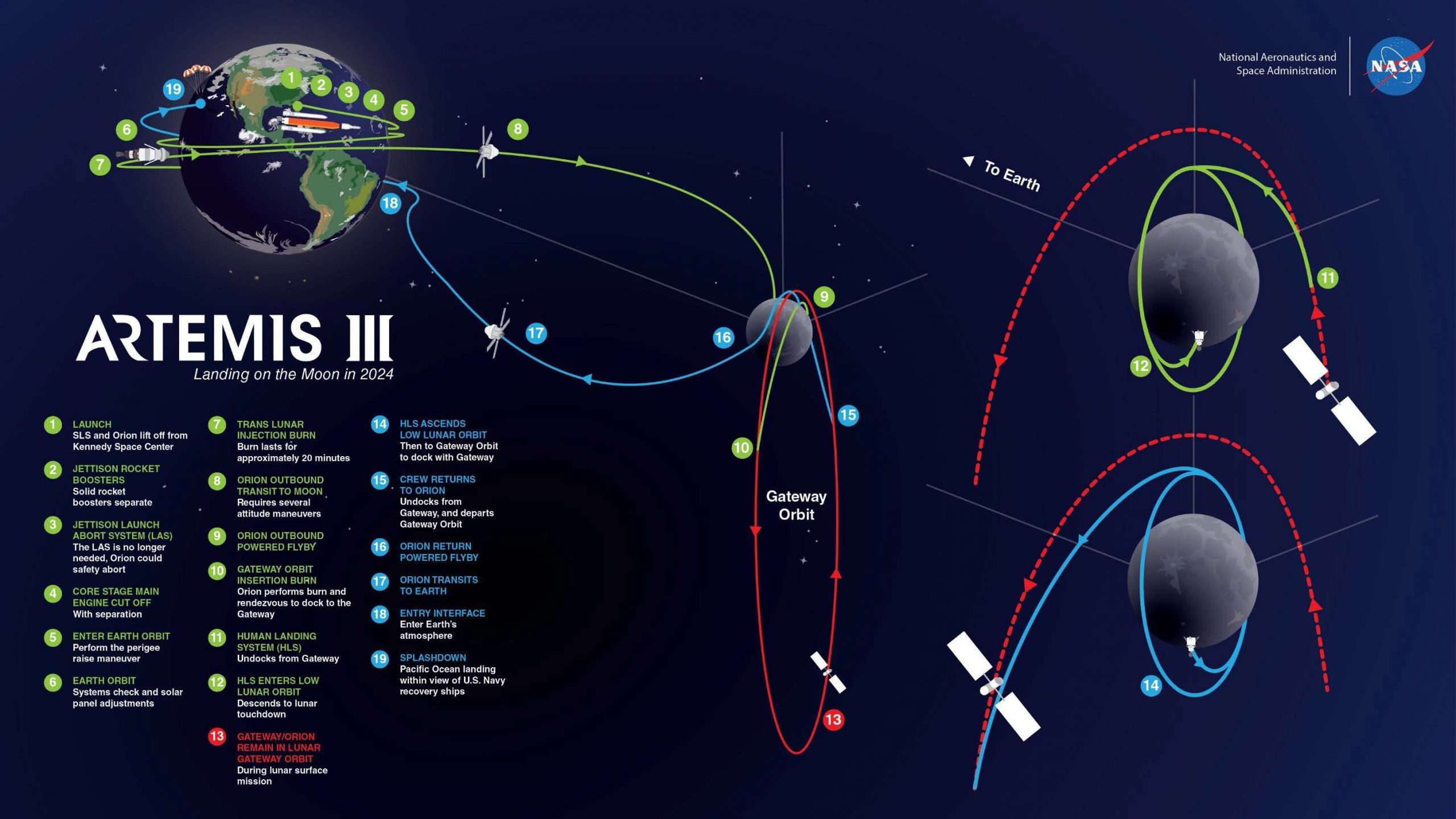

About Artemis III

Artemis III is the second crewed mission of the program, and the first to land astronauts on the Moon. The crew will visit the Moon’s south pole to search for water, study its surface, test technologies, and learn to work on a world outside Earth.

Michoud Assembly Facility

Michoud Assembly Facility in New Orleans is a world-class manufacturing facility providing vital support to NASA exploration and discovery missions. Michoud is NASA-owned and managed for the agency by the Marshall Space Flight Center. Michoud’s capabilities include the manufacture and assembly of critical hardware components for exploration vehicles under development at Marshall and other NASA centers.

Website: www.nasa.gov/centers/marshall/michoud/

Facebook: facebook.com/nasamaf