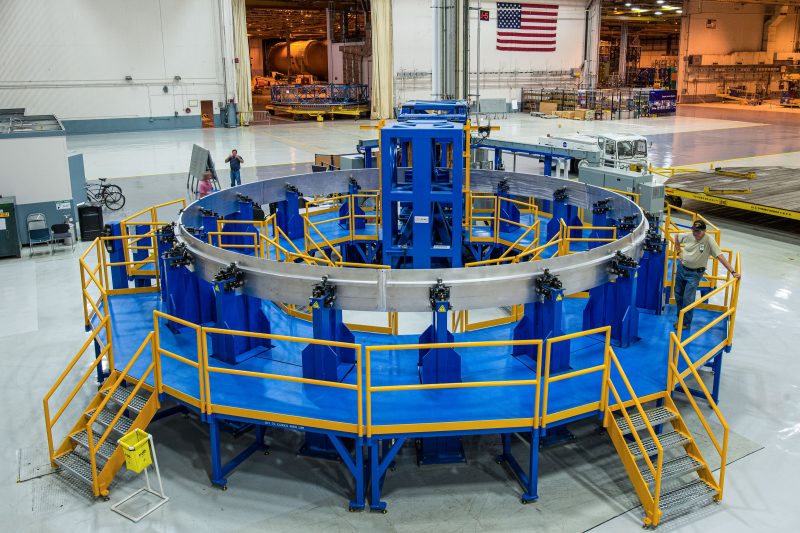

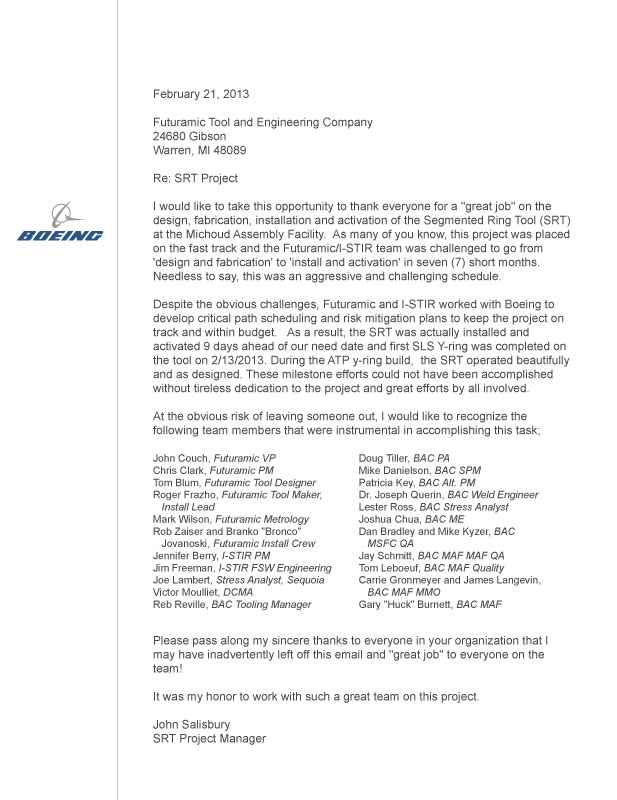

NASA achieved a major milestone in the Artemis V mission with the successful manufacturing of the Y-ring at the Michoud Assembly Facility in New Orleans. The Y-ring, a critical component of the evolved Block 1B configuration of NASA’s Space Launch System (SLS) rocket, will form a portion of the core stage, which is the backbone of the SLS rocket. This innovative work was accomplished using Futuramic’s Segmented Flange Drill Jig Ring Weld Tool (SRT), which was the first tool Futuramic delivered to Boeing for the Artemis program. The Y-ring will serve as the aft ring for the rocket’s liquid hydrogen tank, playing a crucial role in powering the Artemis V mission with its enormous fuel capacity and thrust output. Managed by NASA’s Marshall Space Flight Center, this significant achievement showcases Futuramic’s dedication to advancing aerospace technology through precision engineering and innovative manufacturing processes.

First Components of Artemis V SLS Rocket Manufactured at Michoud

“These photos show how teams at NASA’s Michoud Assembly Facility in New Orleans manufactured the Y-ring that will be used on the evolved Block 1B configuration of the SLS (Space Launch System) rocket. It is one of the first components that will make up a portion of the core stage that will power NASA’s Artemis V mission. The large metal ring will serve as the aft ring for the rocket’s liquid hydrogen tank.

The SLS core stage is the backbone of the SLS rocket, stretching 212 feet from top to bottom, and includes four RS-25 engines at its base. At launch, its two huge liquid propellant tanks provide more than 733,000 gallons of fuel to produce more than 2 million pounds of thrust. Michoud Assembly Facility and the SLS Program are managed by NASA’s Marshall Space Flight Center in Huntsville, Alabama. ” – via NASA Image and Video Library

- Image credit: NASA / Michael DeMocker

- Image credit: NASA / Michael DeMocker

- Image credit: NASA / Michael DeMocker

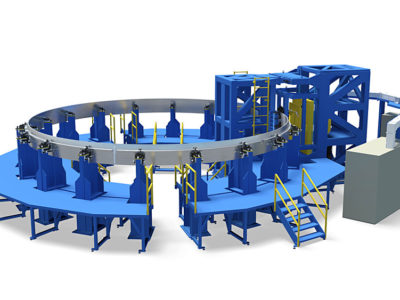

Futuramic’s Segmented Flange Drill Jig Ring Weld Tool (SRT)

Futuramic’s Segmented Flange Drill Jig Ring Weld Tool (SRT) is a sophisticated, precision-engineered tool designed to facilitate the construction and assembly of aerospace components. The SRT is specifically crafted to drill and weld segmented flanges and rings with utmost accuracy, ensuring high-quality joints and seamless integration into rocket structures such as the Space Launch System (SLS). This tool plays a critical role in the assembly process by providing a stable and efficient method for joining large metal rings and flanges, essential components in aerospace engineering. Futuramic’s SRT enhances productivity, consistency, and reliability in the manufacturing of advanced aerospace hardware, making it an invaluable asset in the journey to achieve ambitious space exploration missions.