Futuramic is proud to contribute to NASA’s Artemis IV mission by providing advanced aerospace tooling solutions that support the production of the Space Launch System (SLS) core stage. At NASA’s Michoud Assembly Facility, the recently completed aft dome for the Artemis IV liquid hydrogen tank marks a key milestone in the rocket’s manufacturing process. This critical component was produced using Futuramic’s Circumferential Dome Welding Tool (CDWT), a state-of-the-art system designed to execute high-precision friction stir welding operations.

Advancing Artemis with Precision Aerospace Tooling and Welding Technology

Friction stir welding is a critical process for assembling the SLS core stage, ensuring structural integrity by creating high-strength, defect-free welds in aluminum alloys. The CDWT enables precise circumferential welding of the aft dome, forming a robust and lightweight structure capable of withstanding the extreme environments of launch and space travel. By integrating advanced automation and engineering expertise, Futuramic continues to support NASA and Boeing in the development of next-generation aerospace propulsion systems, furthering the success of the Artemis program and the future of deep space exploration.

“This image shows teams at NASA’s Michoud Assembly Facility lifting a completed dome off of a robotic weld tool on Nov. 21. The dome, which will cap off the aft end of the liquid hydrogen tank, will be used on the core stage of the SLS (Space Launch System) rocket for the agency’s Artemis IV mission. Later, technicians from Boeing – NASA’s prime contractor for SLS – will join the aft dome with five barrels and a forward dome to complete the liquid hydrogen tank. Artemis IV is the first flight of SLS in its Block 1B configuration.

The SLS core stage liquid hydrogen tank holds 537,000 gallons of super-cooled propellant and is one of five unique elements that make up the SLS core stage. Together with the forward skirt, liquid oxygen tank, intertank, and engine section, the liquid hydrogen tank will provide propellant to the four RS-25 engines to produce more than two million pounds of thrust to help launch NASA’s Orion spacecraft, astronauts, and supplies beyond Earth’s orbit to the Moon.” – via NASA Image and Video Library

Supporting Deep Space Exploration

Futuramic plays a vital role in shaping the future of deep space exploration, providing cutting-edge aerospace tooling and structural flight hardware for NASA’s Artemis program. With a team of over 200 skilled professionals, Futuramic designs, manufactures, and maintains critical tooling used in assembling the core stage of the world’s most powerful deep space rocket. This stage, fueled by liquid hydrogen and liquid oxygen, is essential for propelling astronauts and cargo beyond Earth’s orbit.

Beyond tooling, Futuramic contributes large-scale structural flight hardware for Artemis missions, supporting the push toward sustained lunar exploration. Using proprietary manufacturing processes, the company ensures precision, efficiency, and reliability in aerospace production.

As NASA continues its Artemis missions, Futuramic remains a trusted partner, delivering high-quality solutions that drive space exploration forward. With a commitment to innovation and excellence, the company is helping pave the way for future missions to the Moon and beyond.

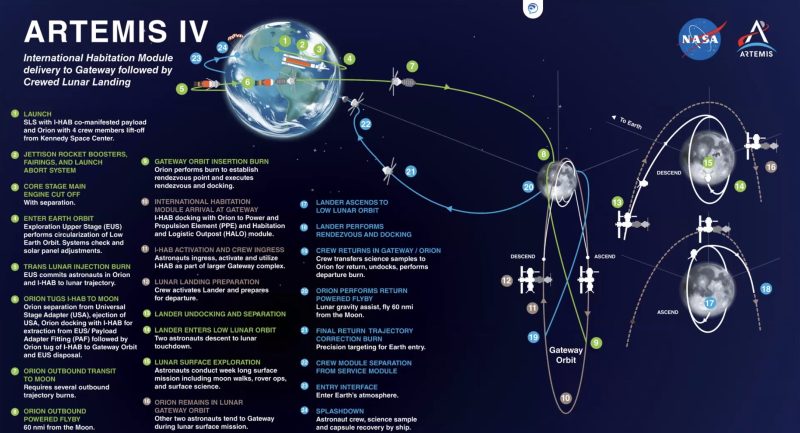

Artemis IV Mission Map

Artemis IV will be the first mission to the Gateway space station in lunar orbit, bringing together an intricate choreography of multiple launches and spacecraft dockings in lunar orbit, and featuring the debut of NASA’s larger, more powerful version of its SLS rocket and new mobile launcher. – NASA