On July 12, 2025, NASA teams at the Michoud Assembly Facility in New Orleans achieved another critical milestone for Artemis III as they successfully moved a massive liquid oxygen (LOX) tank into position for final assembly. The process, known as a “breakover,” lifted the tank from a horizontal orientation to vertical and carefully placed it into Production Cell A — a structure repurposed from Spac Shuttle, engineered and modified by Futuramic.

This precision maneuver sets the stage for technicians to the aft sump subassembly, a crucial component that secures to the tank from within. Once complete, this LOX tank will become part of the core stage of NASA’s Space Launch System (SLS) — the backbone of Artemis missions that will return astronauts to the Moon and eventually pave the way to Mars.

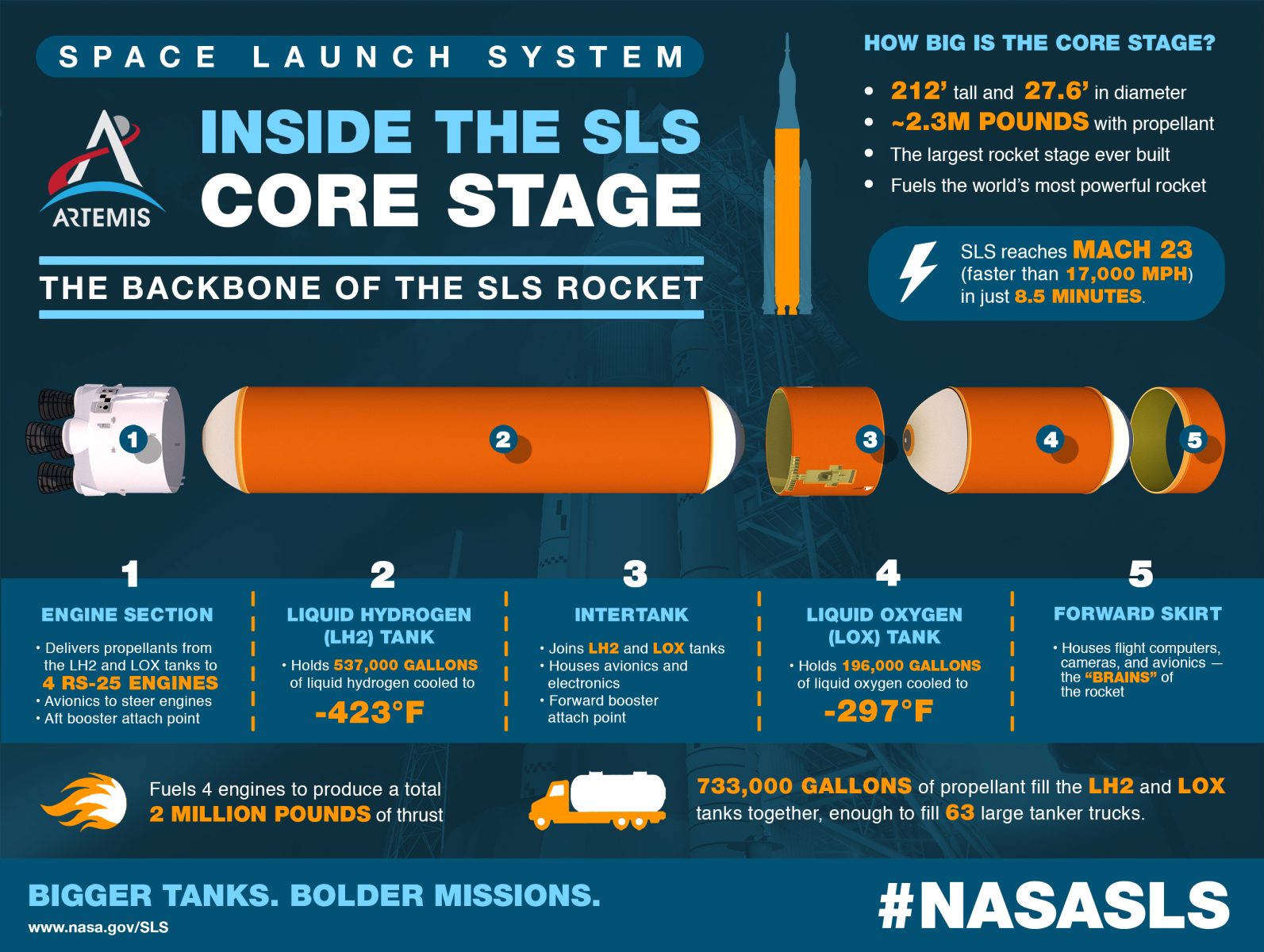

At 212 feet tall, the SLS core stage is the largest rocket stage NASA has ever built. It houses both the liquid hydrogen and liquid oxygen tanks that together hold 733,000 gallons of cryogenic propellant. When fully fueled and integrated with its four RS-25 engines, the stage generates over two million pounds of thrust, powering NASA’s Orion spacecraft, crew, and cargo beyond Earth orbit.

Futuramic is proud to support NASA’s Artemis program through infrastructure like Production Cell A, which enables the complex integration and assembly of critical rocket components. This milestone represents more than just progress in manufacturing — it’s a powerful reminder of the teamwork, engineering, and vision driving humanity’s next steps in space.

Artemis III continues to take shape and bring us one step closer to a sustainable presence on the Moon — and beyond.

“Teams at NASA’s Michoud Assembly Facility in New Orleans lift a liquid oxygen tank from a horizontal to a vertical position and place it into a production cell on July 12. The process, called a breakover, will allow technicians to rappel into the empty tank and install its aft sump subassembly, securing it from the inside. This tank will be used on the core stage of NASA’s SLS (Space Launch System) rocket for its Artemis III mission.

The propellant tank is one of five major elements that make up the 212-foot-tall rocket stage. The core stage, along with its four RS-25 engines, produce more than two million pounds of thrust to help launch NASA’s Orion spacecraft, astronauts, and supplies beyond Earth’s orbit and to the lunar surface for Artemis.” – via NASA Image and Video Library

- Image credit: NASA / Eric Bordelon

- Image credit: NASA / Eric Bordelon

- Image credit: NASA / Eric Bordelon

Watch as teams at NASA Michoud move a liquid oxygen tank for the ArtemisIII mission.

Watch as teams at #NASAMichoud move a liquid oxygen tank for the @NASAArtemis III mission. 🏗️

The massive hardware will form part of the SLS rocket’s core stage. Seen here from earlier this month, it was positioned into a production cell in preparation for the next phase of… pic.twitter.com/tqK7sg8Fp8

— NASA Marshall (@NASA_Marshall) July 22, 2025

Futuramic’s Production Cell A Removable Assembly Platform and OHME

Futuramic’s Production Cell A is a custom-engineered vertical integration cell designed to support the assembly of large-scale aerospace structures, including NASA’s Space Launch System (SLS) core stage components. Purpose-built for precision and safety, the cell enables technicians to access, install, and secure internal subassemblies—such as within liquid oxygen and hydrogen tanks—by allowing vertical positioning and interior entry. This advanced manufacturing infrastructure plays a critical role in supporting NASA’s Artemis missions and deep space exploration goals.

This image captures the successful removal of a finished Liquid Oxygen Tank Forward Dome from Futuramic’s Circumferential Dome Welding Tool (CDWT). This tool positions and secures the Y-Ring, Gore Dome and Upper Dome for circumferential Friction Stir Welding.

NASA SLS Core Stage

“We need the biggest rocket stage ever built for the bold missions in deep space that NASA’s Space Launch System rocket will give us the capability to achieve. This infographic sums up everything you need to know about the SLS core stage, the 212-foot-tall stage that serves as the backbone of NASA’s powerful mega rocket. The core stage includes the liquid hydrogen tank and liquid oxygen tank that hold 733,000 gallons of propellant to power the stage’s four RS-25 engines needed for liftoff and Artemis missions to the Moon and future missions to Mars.” – NASA