Company » Certifications and Awards

Certified Quality and Customer Satisfaction

CERTIFICATIONS

Committed to Excellence

At Futuramic, we optimize value through rigorous quality programs, which are controlled by the Futuramic Quality Assurance Team. Futuramic assures the integrity of all the products we manufacture through the implementation of industry specific certifications, process controls, and traceability. Futuramic’s Quality Assurance organization ensures that quality is recognized and implemented during the earliest phases of program planning, product design, product manufacturing and customer service.

Numerous in-process steps are taken to verify that production is controlled at all times. The Quality Assurance function is implemented by a dedicated QA team who interfaces with program management and the customer to define and document quality requirements and verify compliance at every stage of production. This commitment to quality has led to numerous recognition’s which have been awarded to us by our customers.

ISO 9001:2015 AND AS9100D

In accordance with AS9104A

Without question, the ISO 9001 Registration with the AS Supplement is the most universal and globally recognized quality system today. In March 1998, Futuramic secured ISO 9001 Registration in record time followed with the AS Supplement in March 2005. In conjunction to this, Futuramic employs additional systems such as Kaizen studies.

Scope of Supply. Design, Manufacturing, and Welding of Products, Fixtures, Gages, Layup Molds, Cure Tools, Drill Jigs, and Tooling both Production and Prototype.

Military Critical Technical Data Agreement (MCTDA)

METTS* Approved Vendor

Axient added Futuramic to its MSFC** Safety and Mission Assurance Directorate Evaluated Vendors List for fabrication, welding, heat treatment, machining, and assembly. This approval allows Futuramic to bid on quality sensitive hardware in support of NASA.

*Marshall Engineering Technicians And Trades Support

**Marshall Space Flight Center

AWS CWI Certified

All Futuramic weld inspectors are AWS CWI Certified. Our welders are qualified to AWS Standards. Futuramic has in-house training and qualification capability in all positions and in a wide range of materials.

ITAR

Achieving ITAR registration is evidence of Futuramic’s commitment to comply with policies that control the export and import of defense-related articles and services.

The International Traffic in Arms Regulations (ITAR) and the Export Administration Regulations (EAR) are two important United States export control laws that affect the manufacturing, sales and distribution of technology.

The legislation seeks to control access to specific types of technology and the associated data. Its goal is to prevent the disclosure or transfer of sensitive information to a foreign national.

ITAR contains a United States Munitions List (USML) of restricted articles and services. EAR contains a Commerce Control List (CCL) of regulated commercial items, including those items that have both commercial and military applications.

NADCAP

Futuramic received accreditation from the National Aerospace and Defense Contractors Accreditation Program (Nadcap) for Heat Treatment in September 2018, Welding in September 2019, and NonDestructive Testing (NDT) in August 2023. Futuramic is also currently in the process of pursuing Nadcap certification of our paint process, which is currently on track for completion in the fall of 2023.

Being Nadcap accredited means that we are compliant with and have been audited to the most stringent quality standards in our industry and are capable of processing aerospace quality components. A supplier with Nadcap accreditation is a supplier that has proven to be able to effectively meet the most demanding and stringent customer requirements that exist in the aerospace and defense industries.

Nadcap is recognized as the international quality assurance standard for Special Processes used in the aerospace and defense industries. Nadcap’s distinguished list of subscribers includes Airbus, Boeing, General Dynamics, General Electric, Lockheed Martin, Messier-Bugatti-Dowty and United Technologies to name a few. Suppliers desiring to perform special process for any subscriber in support of the aerospace or defense industries must obtain accreditation which is no small undertaking. Futuramic obtained each accreditation after the initial audit (no further audits required) which is a testament to Futuramic’s commitment to quality and strength of management.

Cybersecurity Maturity Model Certification (CMMC)

Futuramic invests in advanced cybersecurity infrastructure, including a modern ERP (Enterprise Resource Planning) and MRP (Manufacturing Resource Planning) system. These ongoing investments reflect our commitment to staying at the forefront of the industry while ensuring the highest standards of data security, customer protection, and reliable reporting and communication capabilities.

- Using the CMMC Self-assessment protocol Futuramic has scored greater than 3.8, with plans to achieve greater than 4.0 in the next six months.

- Futuramic complies with all 110 requirements of the NIST 800-171 Standard..

Gallery

Awards and Recognitions

Our approach to complete program management means that your job will be handled with care from start to finish. We are thankful to have worked with many great customers through the years and are proud to have been recognized for our hard work. We remain dedicated to high customer satisfaction.

- BAE Future Tech Works Supplier Of The Year Award

- BAE Bronze Supplier Of The Year Award

- 10 Years Supporting Manufacturing Day in Macomb County

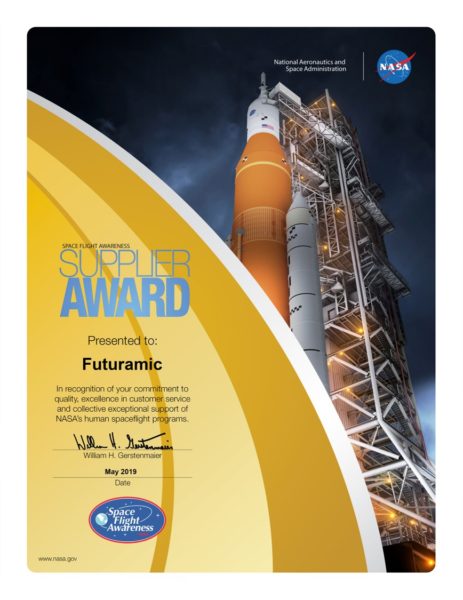

- NASA Space Flight Awareness Supplier Award

- BAE Systems Combat Mission Systems Supplier Excellence Award

- BAE Bronze Supplier Of The Year Award

- BAE Most Improved Supplier Of The Year Award

- BAE Bronze Supplier Of The Year Award

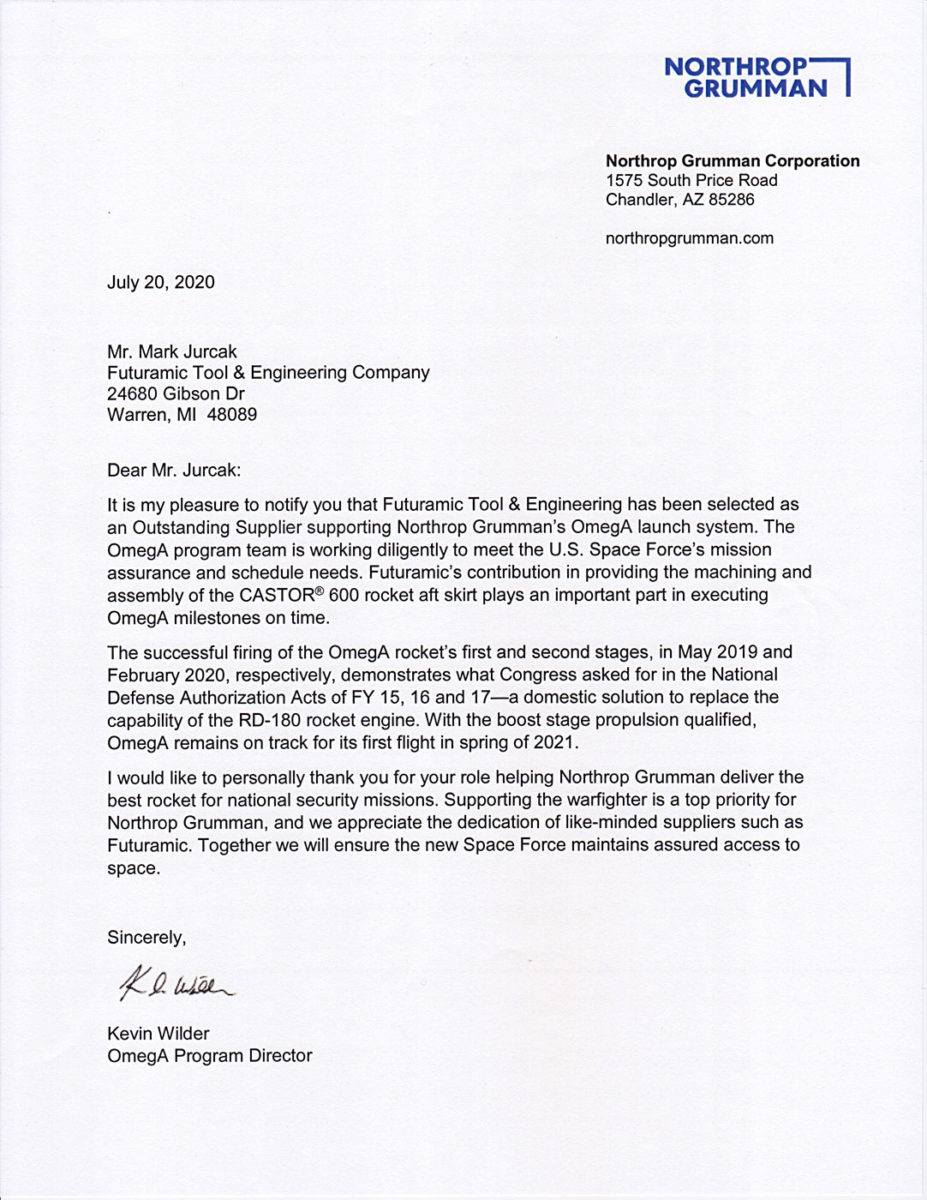

- Northrop Grumman Outstanding Supplier Recipient Letter

- NASA Space Flight Awareness Team Award

- NASA Space Flight Awareness Supplier of the Year Award

- ATK A350-1000 Appreciation

- NASA Small Business Subcontractor Excellence Award

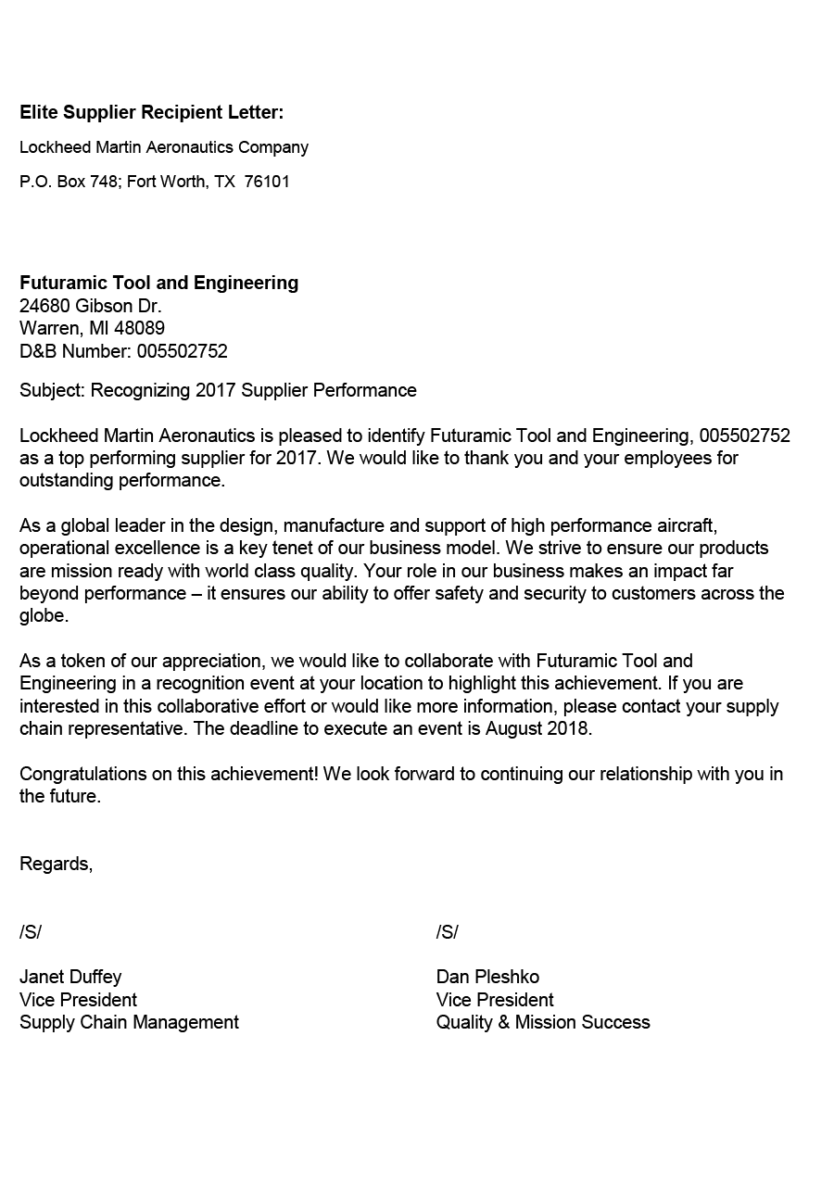

- Lockheed Martin Elite Supplier Recipient Letter

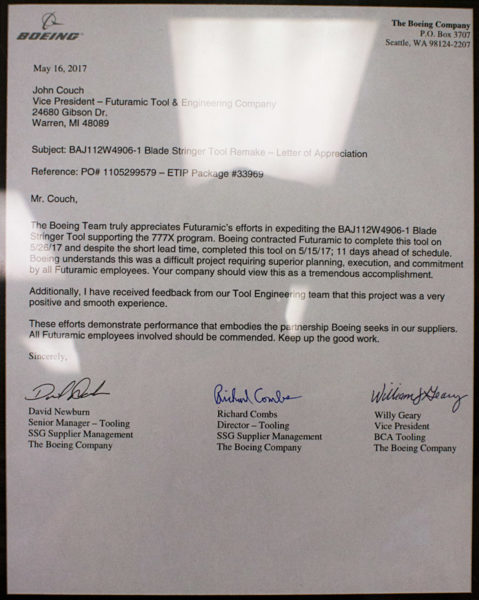

- Boeing 777X Project

- KUKA Systems Aerospace Supplier of the Year Award

- NASA MSFC FY 2013 Subcontractor Excellence Award

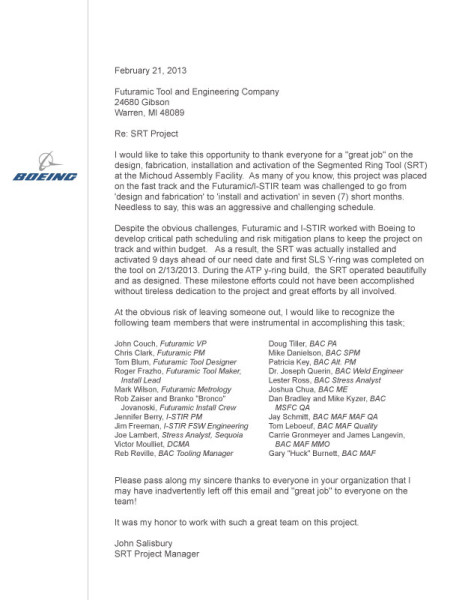

- Boeing SRT Project

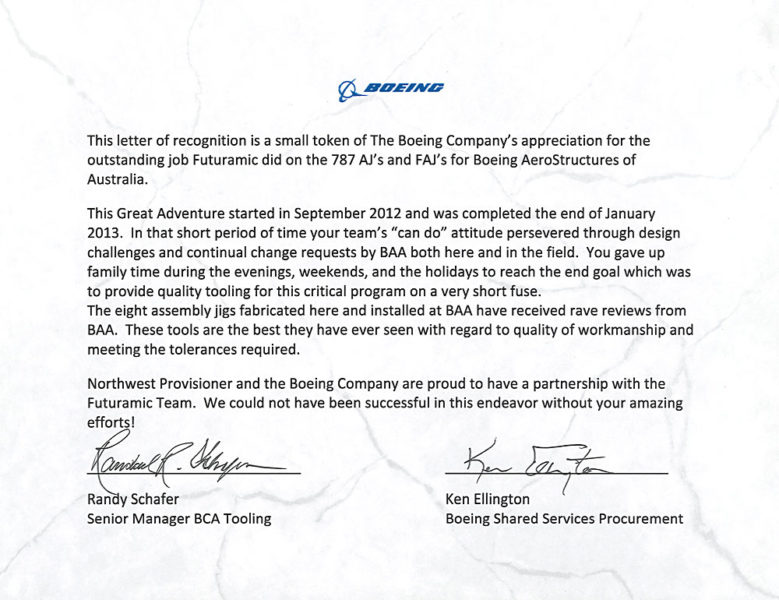

- Boeing 787 AJ’s and FAJ’s Project

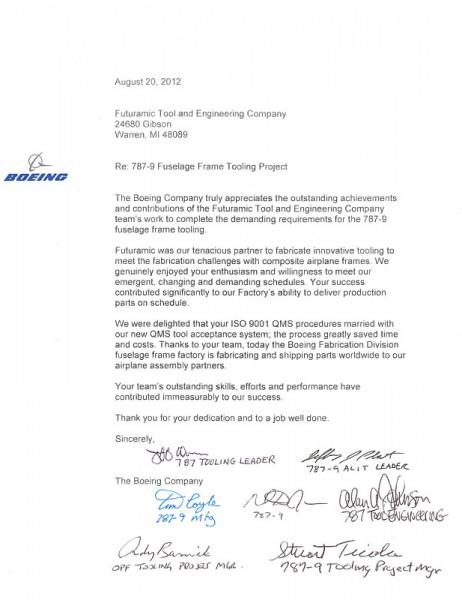

- Boeing 787·9 Fuselage Frame Tooling Project

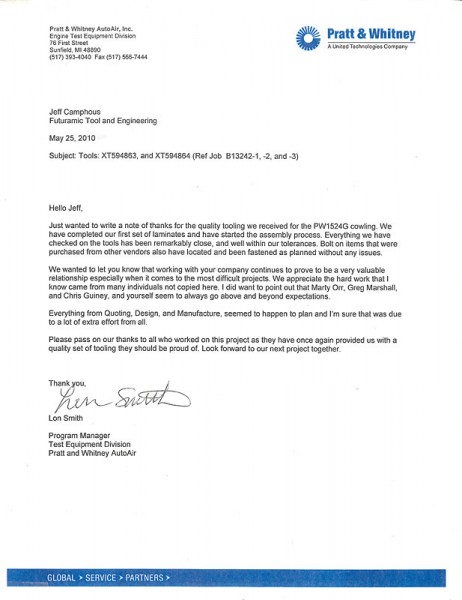

- Pratt & Whitney XT594863. and XT594864 Tooling

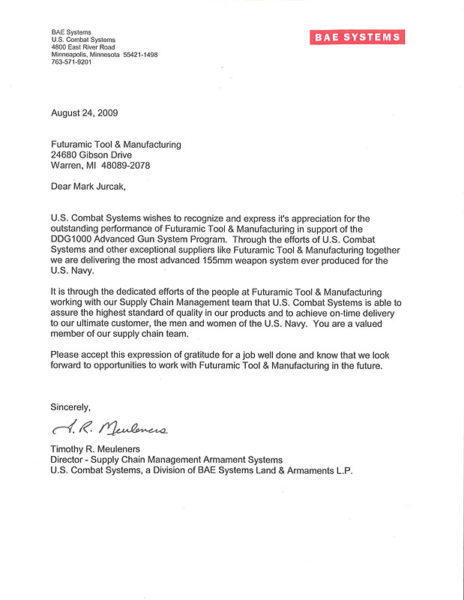

- BAE DDG1000 Advanced Gun System Program

- Boeing Silver Level of Performance

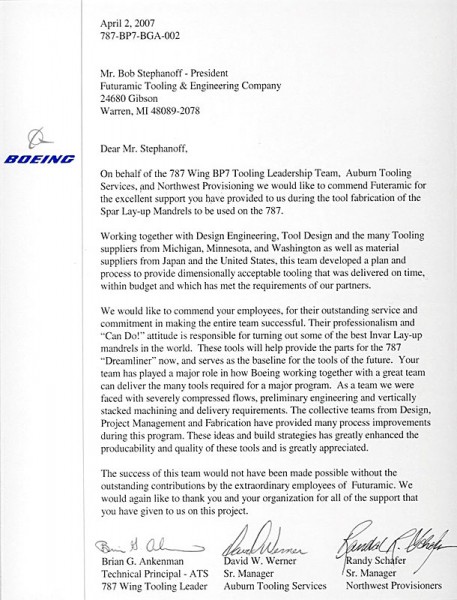

- Boeing 787 Wing BP7 Tooling Project

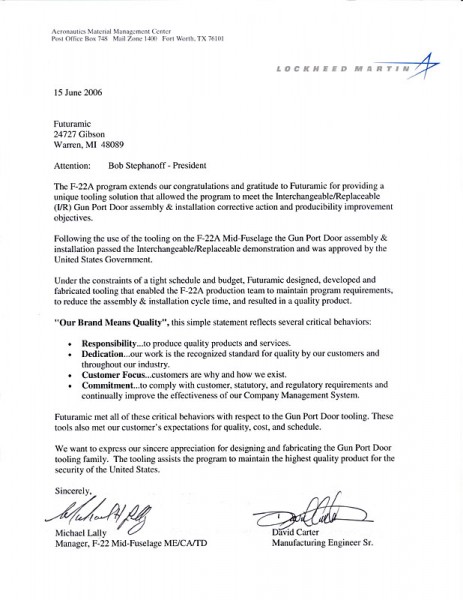

- Lockeed F-22A Mid·Fuselage & Gun Port Door Tooling Project

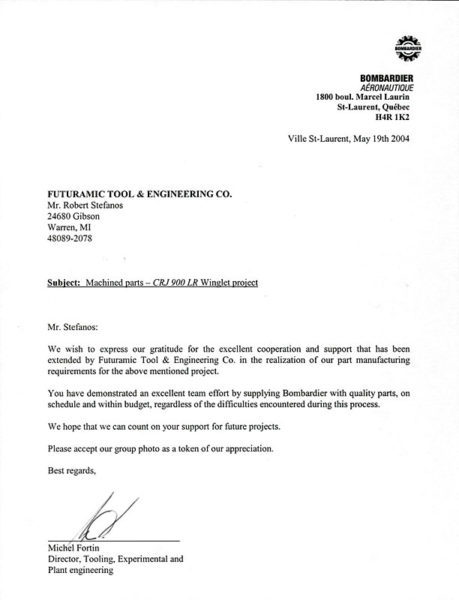

- Bombardier Machined parts CRJ 900 LR Winglet Project

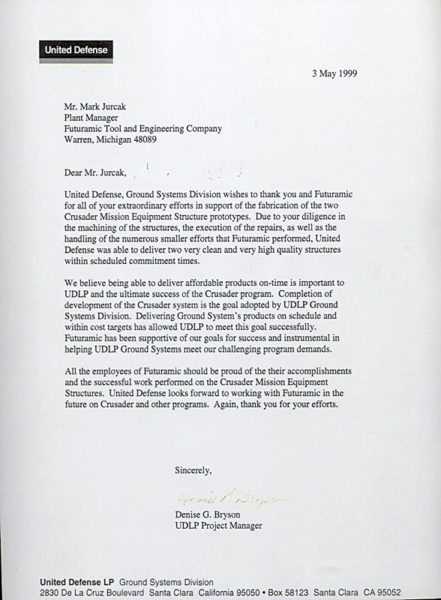

- United Defense Crusader Mission Equipment Structure Project