Recently, a test version of the universal stage adapter for NASA’s upgraded version of the Space Launch System (SLS) rocket has arrived at Building 4619, located in Huntsville, Alabama. This adapter plays a crucial role in connecting the rocket’s enhanced in-space propulsion stage, known as the exploration upper stage, to NASA’s Orion spacecraft as part of the evolved Block 1B configuration of the SLS rocket. Additionally, it serves as a versatile compartment capable of accommodating large payloads, contributing to the expansion of space exploration capabilities. The arrival of this development test article signifies another step forward in NASA’s Artemis program, with the SLS Block 1B variant poised to increase payload capacity for future missions, including Artemis IV. Stay tuned for further updates as engineers at Marshall Space Flight Center conduct rigorous testing to ensure the adapter’s readiness for space missions.

Adapter for Future NASA SLS Flights Readied for Testing

“A test version of the universal stage adapter for NASA’s more powerful version of its SLS (Space Launch System) rocket arrived to Building 4619 at NASA’s Marshall Space Flight Center in Huntsville, Alabama, Feb. 22 from Leidos in Decatur, Alabama. The universal stage adapter will connect the rocket’s upgraded in-space propulsion stage, called the exploration upper stage, to NASA’s Orion spacecraft as part of the evolved Block 1B configuration of the SLS rocket. It will also serve as a compartment capable of accommodating large payloads, such as modules or other exploration spacecraft. The SLS Block 1B variant will debut on Artemis IV and will increase SLS’s payload capability to send more than 84,000 pounds to the Moon in a single launch.

In Building 4619’s Load Test Annex High Bay at Marshall, the development test article will first undergo modal testing that will shake the hardware to validate dynamic models. Later, during ultimate load testing, force will be applied vertically and to the sides of the hardware. Unlike the flight hardware, the development test article has flaws intentionally included in its design, which will help engineers verify that the adapter can withstand the extreme forces it will face during launch and flight. The test article joins an already-rich history of rocket hardware that has undergone high-and-low pressure, acoustic, and extreme temperature testing in the multipurpose, high-bay test facility; it will be tested in the same location that once bent, compressed, and torqued the core stage intertank test article for SLS rocket’s Block 1 configuration. Leidos, the prime contractor for the universal stage adapter, manufactured the full-scale prototype at its Aerospace Structures Complex in Decatur.” – via NASA

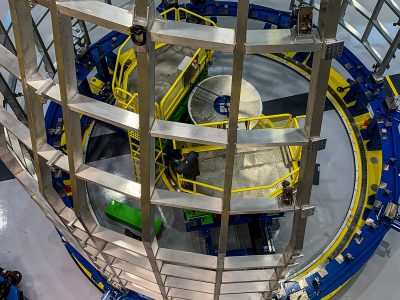

Futuramic’s Vertical Assembly Tool (VAT)

Futuramic continues to play a critical role in advancing aerospace and deep space exploration through its design, construction, and installation of the Vertical Assembly Tool (VAT) for NASA’s Space Launch System. As part of the Integrated Spacecraft and Payload Element (ISPE), the Universal Stage Adapter (USA) serves as a vital interface between the Payload Adapter and the Multi-Purpose Crew Vehicle (MPCV) spacecraft. Futuramic’s VAT facilitates the precise assembly of the USA, ensuring structural integrity and optimal performance during launch and payload deployment. With the USA providing structural and data interfaces to the spacecraft adapter and accommodating additional cargo for exploration missions, Futuramic’s contribution underscores its commitment to advancing space technology and enabling future journeys into deep space.

- Image credit: Dynetics

- Image credit: Dynetics

- Image credit: Dynetics

- Image credit: Dynetics

- Image credit: Dynetics

- Image credit: Dynetics