In a significant milestone for the future of space habitats, Sierra Space recently conducted a historic burst test of its Large Inflatable Fabric Environment (LIFE) habitat, aimed at advancing expandable space station technology. This test, supported by NASA, is a critical step towards realizing the Orbital Reef commercial space station. The successful test marks a giant leap in microgravity research and manufacturing capabilities, essential for the burgeoning low-Earth orbit economy.

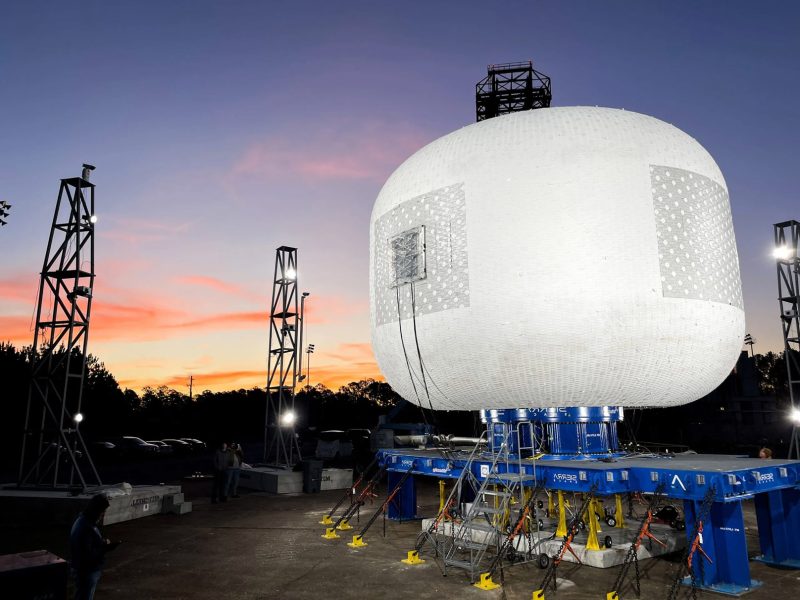

Sierra Space’s LIFE habitat on the test stand at NASA’s Marshall Space Flight Center ahead of a burst test. The LIFE habitat will be part of Blue Origin’s commercial destination, Orbital Reef. Image Credit: Sierra Space

The test took place at NASA’s Marshall Space Flight Center in Huntsville, Alabama, where Sierra Space’s LIFE habitat underwent rigorous evaluation. The LIFE habitat is designed to support the Orbital Reef space station, a collaborative effort led by Blue Origin and Sierra Space, with partners including Boeing, Redwire Space, Genesis Engineering Solutions, and Arizona State University. The Orbital Reef aims to provide a versatile commercial space station in low-Earth orbit, supporting various activities from research to manufacturing.

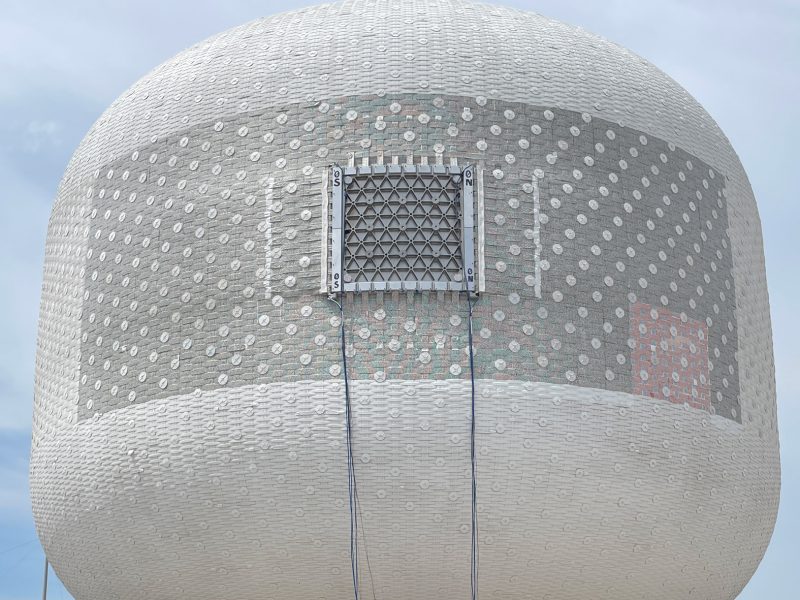

A key component of the LIFE habitat’s burst test was the metallic window sub-structure or “blanking plate,” built by Futuramic. This plate is a critical metallic structure inserted into the softgoods shell to emulate future design components such as windows, robotic arms, or antenna attachment points. For the burst test, a steel blanking plate was used as a stand-in for a future window, ensuring the habitat could withstand the extreme conditions of space.

A close-up view of a detached blanking plate from the Sierra Space’s LIFE habitat structure following its full-scale ultimate burst pressure test at NASA’s Marshall Space Flight Center in Huntsville, Alabama. The plate is used to test the concept of a habitat window. Image Credit: Sierra Space

NASA’s support for this burst test is part of its broader initiative to foster a robust low-Earth orbit economy, leveraging commercial partnerships to develop next-generation space habitats and technologies. The successful test of the LIFE habitat not only demonstrates the viability of expandable habitats but also sets the stage for future missions and advancements in space exploration and commercial utilization.

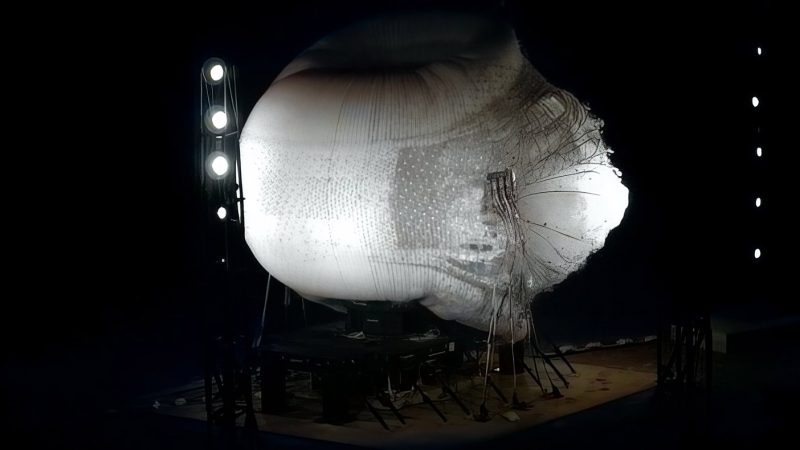

The second Ultimate Burst Pressure test of our LIFE 285 structure at NASA Marshall well exceeded NASA’s recommended 4x safety levels. Image Credit: Sierra Space

Sierra Space Heralds Giant Leap in Microgravity Research and Manufacturing with Historic Test of Expandable Space Station Technology

“Sierra Space, a leading commercial space-tech company that is Building a Platform in Space to Benefit Life on Earth®, announced today that its expandable space station technology successfully passed a seventh key validation test, and second full-scale structural test, at NASA’s Marshall Space Flight Center in Huntsville, Alabama. The results herald a giant leap towards building the world’s first end-to-end business and technology platform in Low Earth Orbit, enabling humanity to find the answers to some of the toughest problems faced on Earth.

Completion of the successful Ultimate Burst Pressure test, which occurred on June 18 in collaboration with ILC Dover (an Ingersoll Rand Business) and NASA, accelerates Sierra Space’s revolutionary softgoods technology towards on-orbit operations. Planned for an initial stand-alone pathfinder mission before the end of the decade, the technology will also feature as a key element of the Orbital Reef commercial space station. The test will close out Milestone #8 for Orbital Reef with Blue Origin under NASA’s Commercial Low Earth Orbit Development Program.” – via Sierra Space

Advancing Next-Gen Space Station Tech with Sierra Space and NASA®

NASA Supports Burst Test for Orbital Reef Commercial Space Station

“An element of a NASA-funded commercial space station, Orbital Reef, under development by Blue Origin and Sierra Space, recently completed a full-scale ultimate burst pressure test as part of the agency’s efforts for new destinations in low Earth orbit.

This milestone is part of a NASA Space Act Agreement awarded to Blue Origin in 2021. Orbital Reef includes elements provided by Sierra Space, including the LIFE (Large Integrated Flexible Environment) habitat structure.

Teams conducted the burst test on Sierra Space’s LIFE habitat structure using testing capabilities at NASA’s Marshall Space Flight Center in Huntsville, Alabama. The inflatable habitat is fabricated from high-strength webbings and fabric that form a solid structure once pressurized. The multiple layers of soft goods materials that make up the shell are compactly stowed in a payload fairing and inflated when ready for use, enabling the habitat to launch on a single rocket.” – via NASA

NASA Conducts 2nd Full-Scale Inflatable Habitat Burst Pressure Test

Futuramic’s Full Scale Burst Blanking Plate

As we move closer to realizing the vision of commercial space stations like Orbital Reef, the contributions of companies like Futuramic, with their precision engineering and innovative solutions, remain indispensable. The historic burst test of the LIFE habitat signifies a monumental step towards a future where space is more accessible for research, manufacturing, and beyond.

Sierra Space’s LIFE®Habitat

In the ever-evolving landscape of space exploration and commercialization, Sierra Space’s Large Integrated Flexible Environment (LIFE) technology stands as a pioneering concept that will reshape how humans live and work in space.

Sierra Space’s LIFE (Large Integrated Flexible Environment) habitat launches on a conventional rocket and inflates on-orbit to a large structure that is three stories tall, and 27 feet in diameter. It can comfortably sleep four astronauts, with additional room for science experiments, exercise equipment. Available to the occupants are a medical center and Sierra Space’s Astro Garden® system, which can grow fresh produce for astronauts on long-duration space missions.

Image Credit: Sierra Space