NASA and Boeing have initiated a contract agreement for the production of 10 Space Launch System (SLS) core stages and up to eight Exploration Upper Stages (EUS) to support future Artemis Missions.

NASA and Boeing have initiated a contract agreement for the production of 10 Space Launch System (SLS) core stages and up to eight Exploration Upper Stages (EUS) to support future Artemis Missions.

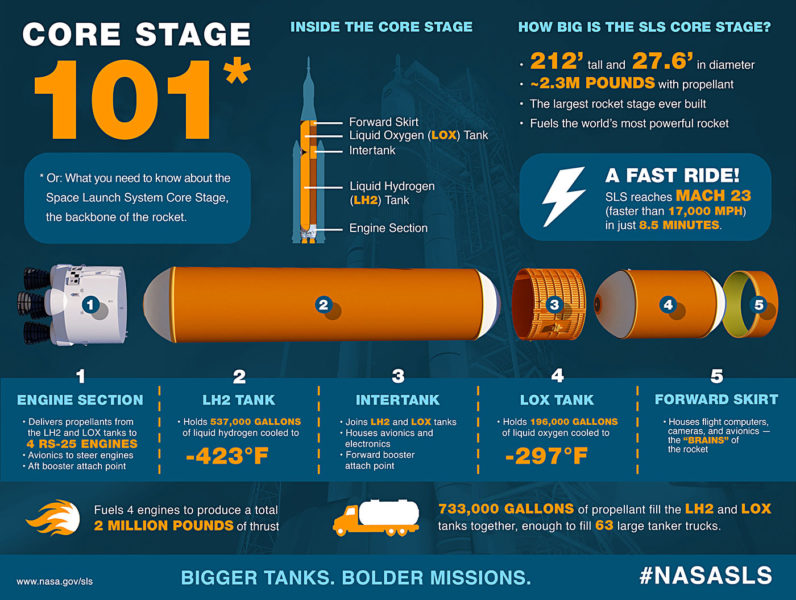

Per NASA, the agency intends to work with Boeing, the current lead contractor for the core stages of the rockets that will fly on the first two Artemis missions, for the production of SLS rockets through the next decade. The core stage is the center part of the rocket that contains the two giant liquid fuel tanks. Towering 212 feet with a diameter of 27.6 feet, it will store cryogenic liquid hydrogen and liquid oxygen and all the systems that will feed the stage’s four RS-25 engines. It also houses the flight computers and much of the avionics needed to control the rocket’s flight.

“What this means for Futuramic is simple. It’s the ability to leverage our knowledge, experience, and advanced manufacturing processes to make future core stage production quicker and more efficient.” explained Futuramic’s Vice President John Couch. Adding, “We look forward to continuing to play an important part in the continued development of the SLS, and utilizing ‘lessens learned’ from the the first core stage production.”

Simulators mounted on a Liquid Hydrogen Tank during structural testing at Marshal Space Flight Center in Huntsville Alabama. Photo Credit: NASA

NASA has provided initial funding and authorization to Boeing to begin work toward the production of the third core stage and to order targeted long-lead materials and cost-efficient bulk purchases to support future builds of core stages. This action allows Boeing to manufacture the third core stage in time for the 2024 mission, Artemis III, while NASA and Boeing work on negotiations to finalize the details of the full contract within the next year. The full contract is expected to support up to 10 core stages and up to eight Exploration Upper Stages (EUS).

Futuramic designed, built, installed and support much of the tooling shown in this picture including the tooling to build the flight hardware show. Photo Credit: NASA

Futuramic’s president Mark Jurcak noted, “Futuramic is proud to be a supplier to the Space Launch System (SLS), America’s deep space exploration launch vehicle. Over the last five years Futuramic has made numerous friction stir weld tools, assembly tools, platforms, overhead lift devices and structural simulators for use by Boeing in the construction of the Space Launch System rocket at the NASA Michoud Assembly Center in New Orleans, Louisiana (MAF).” Mark went on to explain, “Partners like Boeing, NASA, and Futuramic play an important role in growing our regional and local economies. We are proud to continue our partnership with them to help grow our region’s space exploration industry.”

Simulators mounted on a Liquid Oxygen Tank in preparation for shipment from the NASA Michoud Assembly Facility in New Orleans LA Marshal Space Flight Center in Huntsville Alabama. Photo Credit: NASA

This is really great news for Futuramic, who works directly with Boeing and has contributed more than 100 parts currently used in the SLS production. Futuramic designed and built the tools to install the rocket’s engines, and assemble the liquid oxygen and liquid hydrogen tanks used to fuel the rocket. It also produced the equipment that creates the domes for those tanks.

Futuramic is one of 78 Michigan businesses that are contributing to NASA’s Artemis program.

For more about the Space Launch System (SLS) rocket core stages and NASA’s commitment to the future or Artemis please visit:

- www.boeing.com/space/space-launch-system

- www.nasa.gov/feature/nasa-commits-to-future-artemis-missions-with-more-sls-rocket-stages

Space Launch System Core Stage 101: We need the biggest rocket stage ever built for the bold missions in deep space that NASA’s Space Launch System rocket will give us the capability to achieve. Photo Credit: NASA

About Futuramic

As a supplier, Futuramic is helping NASA and Boeing, the SLS prime contractor, to complete assembly of the rocket’s core stage for EM-1 at NASA’s Michoud Assembly Facility in New Orleans. Most recently, Futuramic designed and completed initial assembly on both simulators for the liquid oxygen tank and liquid hydrogen tank structural test articles. The two test articles have identical structures to flight tanks that are part of the rocket’s massive core stage. On a mission, the tanks hold 733,000 gallons of propellant to help power the rocket’s four RS-25 engines that will send SLS and Orion to the Moon. During tests, the simulators allow engineers to apply millions of pounds of force to the tanks to test their strength and ensure SLS is safe to fly.