Services

65+ years of advanced manufacturing experience

Services

Committed to quality

Our commitment to quality and complete customer satisfaction means that you’ll be working with the best people. There is no “B” team here. From large to small, simple to complex, domestic to international, Futuramic has the equipment, skills, and experience to provide the very best engineering, manufacturing, fabrication, certification, and installation services. We offer a wide range of capabilities will take your project from an idea into reality. Let’s build great things together.

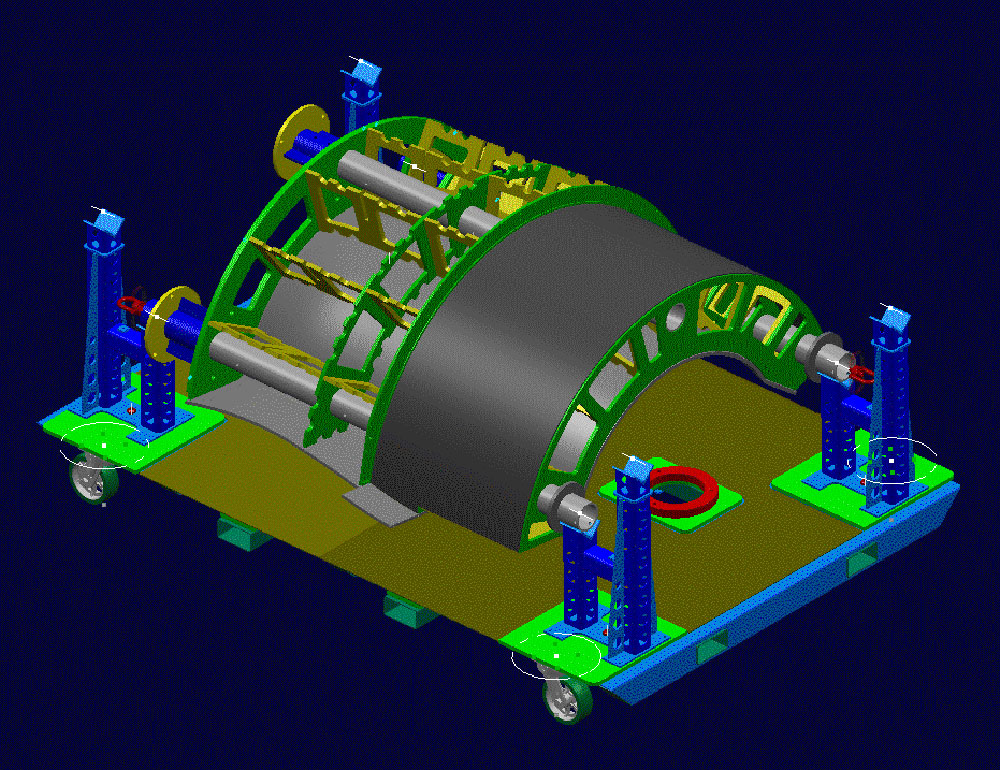

Engineering

Futuramic’s engineering facilities employ the very latest CAD/CAM and Server technology, along with up-to-date data communications, enabling the receiving, processing, and return of data to customer specifications in virtually any format.

Fabrication

The fabrication facility is not a normal weld shop. Futuramic applies the same discipline to fabrication as we do to machining. Our highly-skilled and experienced associates have access to the latest state-of-the-art equipment.

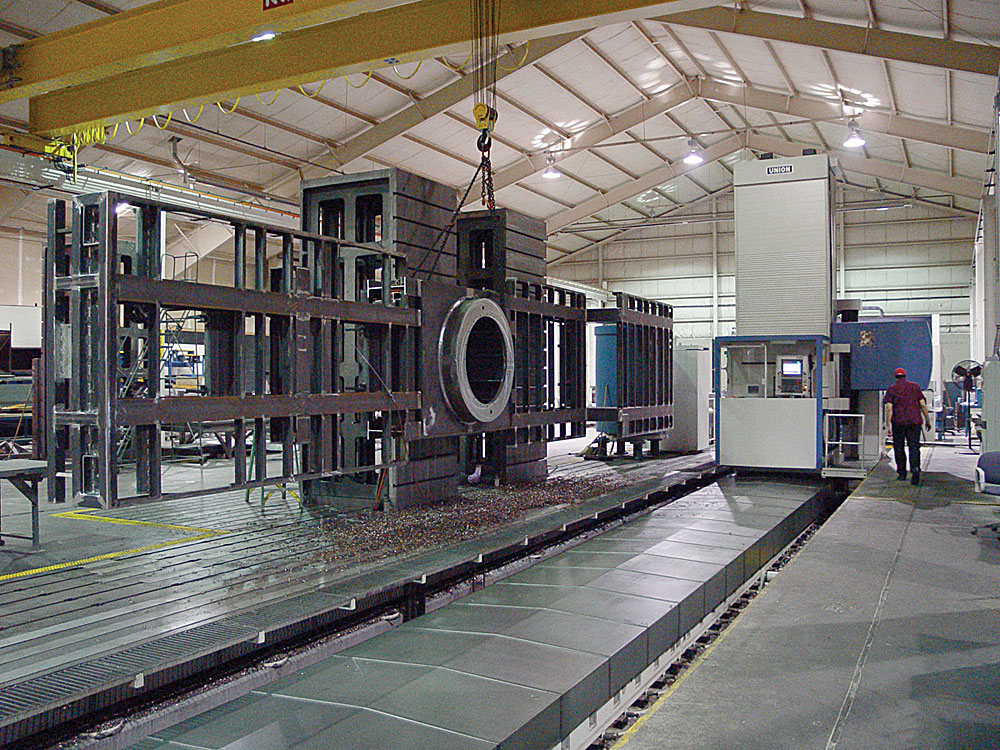

Manufacturing

Futuramic has a wide variety of CNC machines with access to all of our machining data. Each machine is equipped with a computer capable of post processing and data downloading of NC programs to the machine control memory or through DNC. A single source DNC system has been avoided and computer failures will not halt the manufacturing process.

Inspection

Through the online inspection and certification process at Futuramic, six servo driven DCC coordinate measuring machines receive and return data through the network. Using CAPPS, AVAIL, and PC-DMIS software, these machines may be programmed offline or at the console by the operator using surface, wireframe, and/or 3D solid data. Inspection results are returned to the file server for compilation, printing and storage. Our milling machines, laser systems, CMM inspection equipment, and all master inspection gages are laser calibrated annually and undergo regular scheduled maintenance checks to ensure accuracy and reliability.

Installation

Futuramic has several build and installation teams that are experienced at installing tools. A 53-ft. mobile tool shop trailer provides support at field installations. The trailer is configurable to meet the needs of any job, but always contains power generation, welding, milling, and grinding equipment along with a full complement of hand tools to support the build team. The on-site availability of tooling resources dramatically increases the speed of complex installations at a customer’s site.